If you are building a new vape brand from scratch, dry herb vaporizers can be a powerful product line with strong margins and a loyal user base. This guide explains how dry herb vapes work, the main heating methods, modern ceramic technology and what you should look at when working with an OEM factory in China.

https://aovape.com/vaporizers/wanderbox-marijuana-vaporizer/

🌿 What Is a Dry Herb Vaporizer?

Dry herb vaporizers heat ground botanical material to a temperature where active compounds turn into vapor, but the herb does not burn like in a traditional pipe or joint. Compared with oil pens and cartridges, they do not need pre-filled oil, so they appeal to users who prefer loose flower and more “traditional” cannabis rituals.

- Differentiate your line from the crowded disposable oil vape market

- Attract more experienced users who care about flavor, temperature control and hardware quality

An Example of a Market-Ready Dry Herb Vaporizer Kit

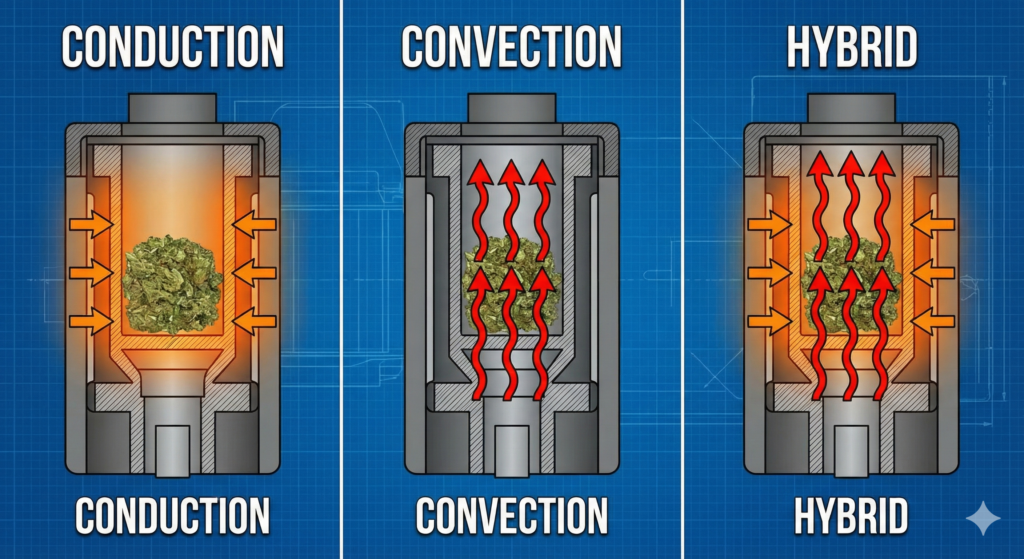

🔥 Conduction vs Convection vs Hybrid Heating

Nearly all dry herb vaporizers rely on one of three heating methods: conduction, convection, or a hybrid of both.

🔸 Conduction Heating

Conduction vapes heat the herb by direct contact with a hot surface, usually a metal or ceramic oven. They heat up fast and are easier to design and manufacture, which makes them attractive for entry-level price points. The downside is uneven heating if the chamber isn’t well designed or the material isn’t stirred during the session.

🔹 Convection Heating

Convection vapes heat incoming air and push it through the herb, cooking it evenly without direct contact. These offer better flavor and smoother vapor but are more expensive and complex to build.

⚫ Hybrid Heating

Hybrid vapes combine conduction chamber walls with convection airflow. They heat up quickly and provide more balanced vapor production, making them ideal for mid to high-end models.

📊 Heating Method Comparison Table

| Heating Type | How It Works | User Experience | Pros for Startup Brand | Cons for Startup Brand |

|---|---|---|---|---|

| Conduction | Herb touches a hot oven surface | Fast heat-up, strong first hits, risk of hot spots | Low cost, simple design, easy to scale | Needs careful temp control and design to avoid burning |

| Convection | Hot air flows through the herb | Clean flavor, even extraction, slower to heat | Great for premium models | Higher cost, more complex structure |

| Hybrid | Combines wall heating and airflow | Fast vapor, good flavor and consistency | Balanced solution for most brands | Requires experienced engineering |

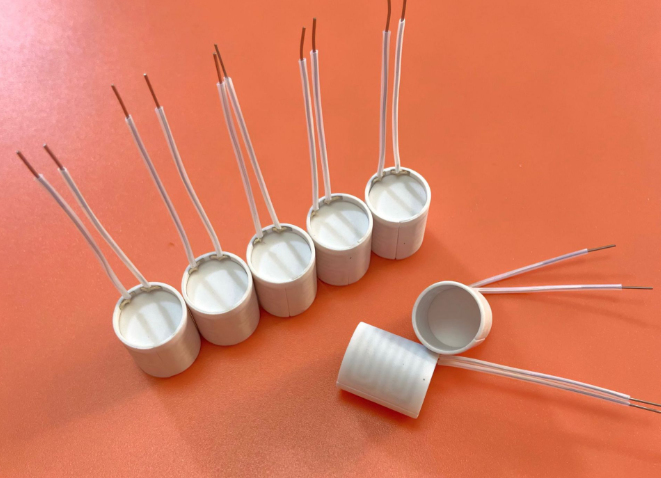

🔬 Modern Ceramic Heating Chambers

Ceramic is widely used in dry herb vaporizers because it is chemically inert, withstands high temperatures, and does not interfere with flavor. Porous ceramic structures improve heat distribution and reduce the chance of hot spots.

Compared to stainless steel, ceramic provides a smoother heat-up curve and eliminates metallic taste — critical for flavor-conscious users.

Common Ceramic Designs

- Full ceramic chamber: High-end, easy to clean, even heat

- Ceramic-coated metal chamber: Budget-friendly with improved taste

- Ceramic heating plate: Modular option paired with stainless or glass walls

herb vaporizer ceramic heat

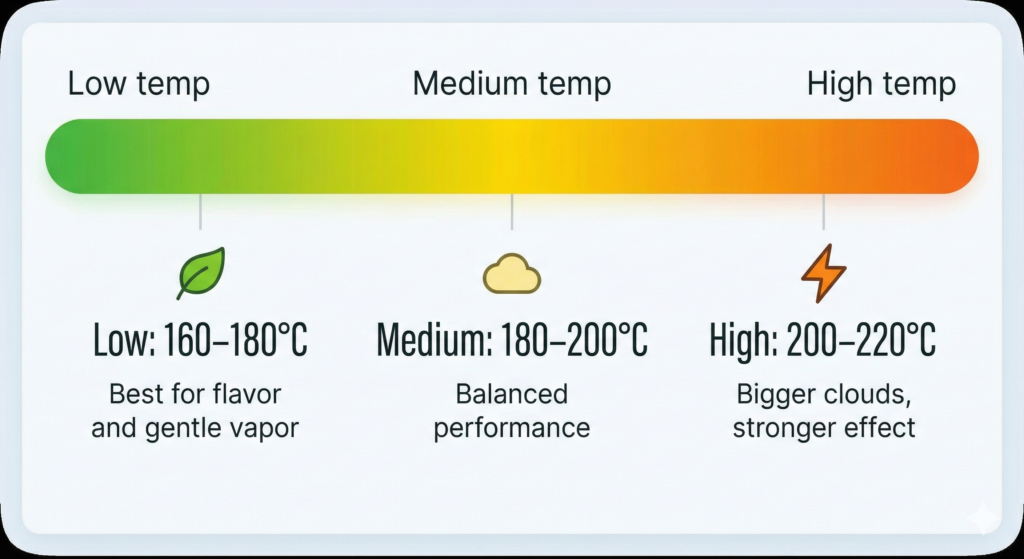

🌡️ Temperature Control and Terpene Profile

Different temperatures release different active compounds and flavors. This is where dry herb vapes really shine compared to smoking.

- Low (160–180°C): Best for flavor and gentle vapor

- Medium (180–200°C): Balanced performance

- High (200–220°C): Bigger clouds, stronger effect, heavier flavor

dry Herb Vaping Temperature Spectrum and FlavorVapor Effects

For new brands, we recommend using 3 preset temperature levels with easy-to-understand labels or color lights: “Flavor / Balanced / Cloud.”

🧠 Key Design Decisions for Startup Brands

📏 Chamber Size & Airflow

Chamber size affects dose per session and battery requirements. Aim for 0.2–0.3g for portability. Ensure an isolated airpath (ceramic, glass, or stainless steel) to avoid contamination.

🔋 Battery & Session Type

Most portable vapes balance battery capacity and form factor. First-time brands should opt for built-in battery with session mode (e.g., 4–6 min auto-shutoff) for safety and ease of use. Vibration alerts are a plus.

🏭 Working With an OEM Manufacturer

Choosing the right partner is crucial. A good OEM helps with design, tooling, compliance, and post-sales support.

Ask about:

- Materials and certifications (ROHS, REACH)

- Durability tests: drop, temp cycle, button life

- Compliance support: MSDS, CE, FCC, etc.

Inside AOVAPE’s Modern OEMODM Dust-Free Manufacturing Facility

Look for a factory that offers small batch prototyping, visual customization, and helps define your user persona—not just the lowest quote.

🚀 Positioning Your First Dry Herb Vape

Start with one core model that uses hybrid or well-designed conduction heating, a ceramic chamber, and 3 preset temperatures. Focus on flavor, ease of use, and safety. Then expand into related categories like wax pens, 510 batteries, or oil pens.

❓ FAQ for New Vape Founders

Q1: Is dry herb vaping safer than smoking?

It avoids combustion and harmful byproducts, but still requires legal and responsible use. Don’t make medical claims.

Q2: How long does a ceramic chamber last?

Months to years with regular cleaning. Ceramic is stable under vape temperatures.

Q3: Which heating type should I choose?

Start with hybrid or conduction for reliability and cost-efficiency. Save full convection for premium models later.

👉 Explore our flagship dry herb vaporizer WanderBox to see how we combine hybrid heating, ceramic tech, and startup-friendly design.