Wax pens remain one of the most profitable and brand-driven categories in the concentrate vaporizer market. For startup vape brands and distributors, launching a custom wax pen is often the fastest way to build a recognizable product line with strong margins and loyal users.

Compared with 510 oil pens or generic disposables, wax pens give your brand much more room to shape performance, design, and positioning. That is why most serious concentrate brands include at least one signature wax pen in their hardware lineup.

This guide explains how wax pens work, the most common coil and heating designs on the market, and what you should focus on when working with an OEM factory in China to build your own branded device from the ground up.

🧪 What Is a Wax Pen and Why Customization Matters

A wax pen (also known as a dab pen) is designed to vaporize solid concentrates such as wax, shatter, rosin, badder, or crumble. Unlike oil vape pens, wax pens require manual loading and direct heating, which naturally attracts more experienced users who care about power, flavor, and control.

Key differences compared with oil pens:

- The concentrate is loaded manually rather than through a prefilled cartridge.

- The heating surface is in direct contact with the material, making coil design critical.

- Users are more sensitive to flavor accuracy, hit strength, and reclaim buildup.

For a new brand, customizing a wax pen allows you to:

- Differentiate from generic oil pens and disposable products.

- Target experienced users with higher repeat purchase rates and stronger loyalty.

- Control performance, materials, and brand perception instead of just adding a logo.

- Create a true “hero product” supported by content, accessories, and bundles.

From a business perspective, wax pens often deliver higher per-unit margins, support recurring accessory sales (replacement coils, caps, dab tools), and help position your brand as hardware-focused rather than purely consumable.

🔧 Wax Pen Coil Types Explained

The coil (or atomizer) is the core component that defines vapor production, flavor quality, and long-term reliability. Choosing the right coil structure is one of the most important OEM decisions because it directly affects temperature behavior, extraction efficiency, and maintenance frequency.

| Coil Type | Material | Heat-Up Speed | Flavor Output | Best Use Case | OEM Notes |

|---|---|---|---|---|---|

| Quartz Rod Coil | Quartz rods + metal wire | Very fast | Strong, punchy | High-temperature dabbing, cloud chasers | Low cost, easy to drive, ideal for entry-level models |

| Ceramic Donut Coil | All-ceramic heating surface | Moderate | Clean, terpene-forward | Flavor-focused users, low-temp sessions | Best for premium positioning with controlled power |

| Ceramic Bucket / Cup | Ceramic cup with embedded heater | Moderate | Even and consistent | Easy loading, cleaner sessions | Very popular in higher-end dab pens |

| Fritted Quartz | Porous sintered quartz | Moderate to fast | Extremely pure and smooth | Connoisseur-grade concentrates | Higher cost, strong differentiation for premium lines |

OEM insight: Ceramic-based coils dominate premium wax pens due to cleaner flavor and stable heat behavior, while quartz rods remain popular for budget or impact-focused products. A balanced lineup often includes both.

🔥 Heating Styles in Wax Pens

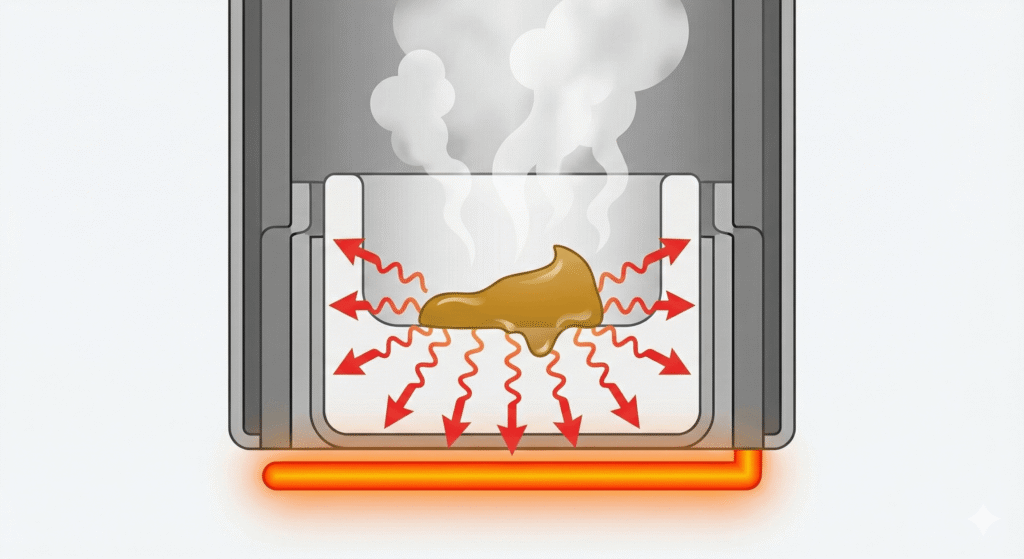

Unlike dry herb vaporizers, wax pens rely almost entirely on conduction heating. The concentrate is vaporized through direct contact with the heating surface rather than hot air circulation.

Main conduction approaches:

- Direct conduction: Extremely fast heat-up and strong vapor output, but requires careful power control to avoid burning.

- Optimized conduction with airflow design: Better heat distribution, smoother vapor, and fewer hot spots, typically used in modern ceramic systems.

Diagram of Ceramic Bucket Heating and Airflow

Performance improvements in modern wax pens come from chamber geometry, airflow management, voltage stability, and thermal tuning—not true convection heating.

When testing samples, always evaluate performance at low, medium, and high power levels to ensure flavor, vapor density, and coil longevity remain consistent.

🛠️ Key Customization Options for Startup Brands

Chamber Design and Capacity

Chamber size defines session length and loading behavior. Most portable wax pens fall between 0.1 g and 0.3 g capacity.

- Smaller chambers favor microdosing and flavor clarity.

- Medium chambers suit daily users.

- Deeper cups reduce splatter but must remain easy to clean.

All-ceramic or ceramic-lined chambers are now standard for mid-to-high tier products due to flavor neutrality and marketing clarity.

Battery Capacity and Power Control

- Typical battery range: 350 mAh to 900 mAh.

- Three-step voltage presets remain the most user-friendly option.

- USB-C charging is expected in modern devices.

Translate technical specs into user-facing benefits such as “all-day battery” or “three smart heat modes” rather than raw numbers.

Airflow, Mouthpiece, and User Experience

Airflow resistance, mouthpiece shape, and splash protection significantly affect perceived quality. Removable or magnetic mouthpieces simplify cleaning and reduce clogging complaints.

Coil Replacement and After-Sales Strategy

Replaceable coils extend device lifespan, reduce warranty claims, and create recurring revenue opportunities. Always confirm real-world coil life and ease of cleaning.

🔗 Example: Cylindra Wax Vaporizer as a Custom Wax Pen Platform

The Cylindra Wax Vaporizer demonstrates how modern wax pen design principles come together in a scalable OEM platform.

- Ceramic-based heating surfaces for clean flavor.

- Balanced conduction heating for fast response without harsh burning.

- Durable metal body suitable for engraving, color customization, and surface treatments.

Platforms like this can support multiple coil options, customized voltage presets, and different packaging tiers to target varied market segments.

🏭 Working With an OEM Wax Pen Manufacturer in China

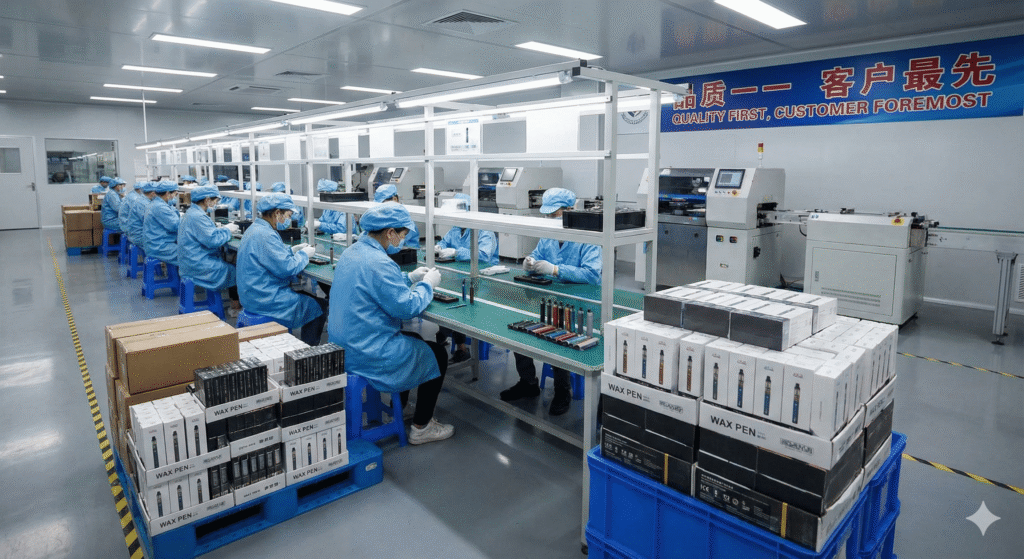

A reliable OEM partner should support more than assembly. Look for transparency in materials, testing procedures, and quality control.

- Clear documentation on ceramics, metals, and insulation materials.

- Real test data on coil life and temperature stability.

- Low-MOQ pilot runs for market validation.

- Support for branding, packaging, and compliance labeling.

Assembly Line at an OEM Vape Manufacturing Facility in China

Always conduct real-world testing by placing samples in the hands of experienced users before committing to large production runs.

🎯 Positioning Your First Wax Pen Product

Most successful startup brands launch with a single flagship wax pen that emphasizes flavor, reliability, and ease of use.

- One main ceramic or fritted quartz model as the hero product.

- Optional quartz variant for cloud-focused users.

- Simple, clearly labeled power modes.

- Transparent communication about materials and safety.

A well-executed wax pen can become the foundation of your hardware portfolio and make future expansion into dry herb vaporizers, 510 batteries, and oil pens far easier.